Our Ambition

Developing novel and credible solutions for a responsible electronics value chain

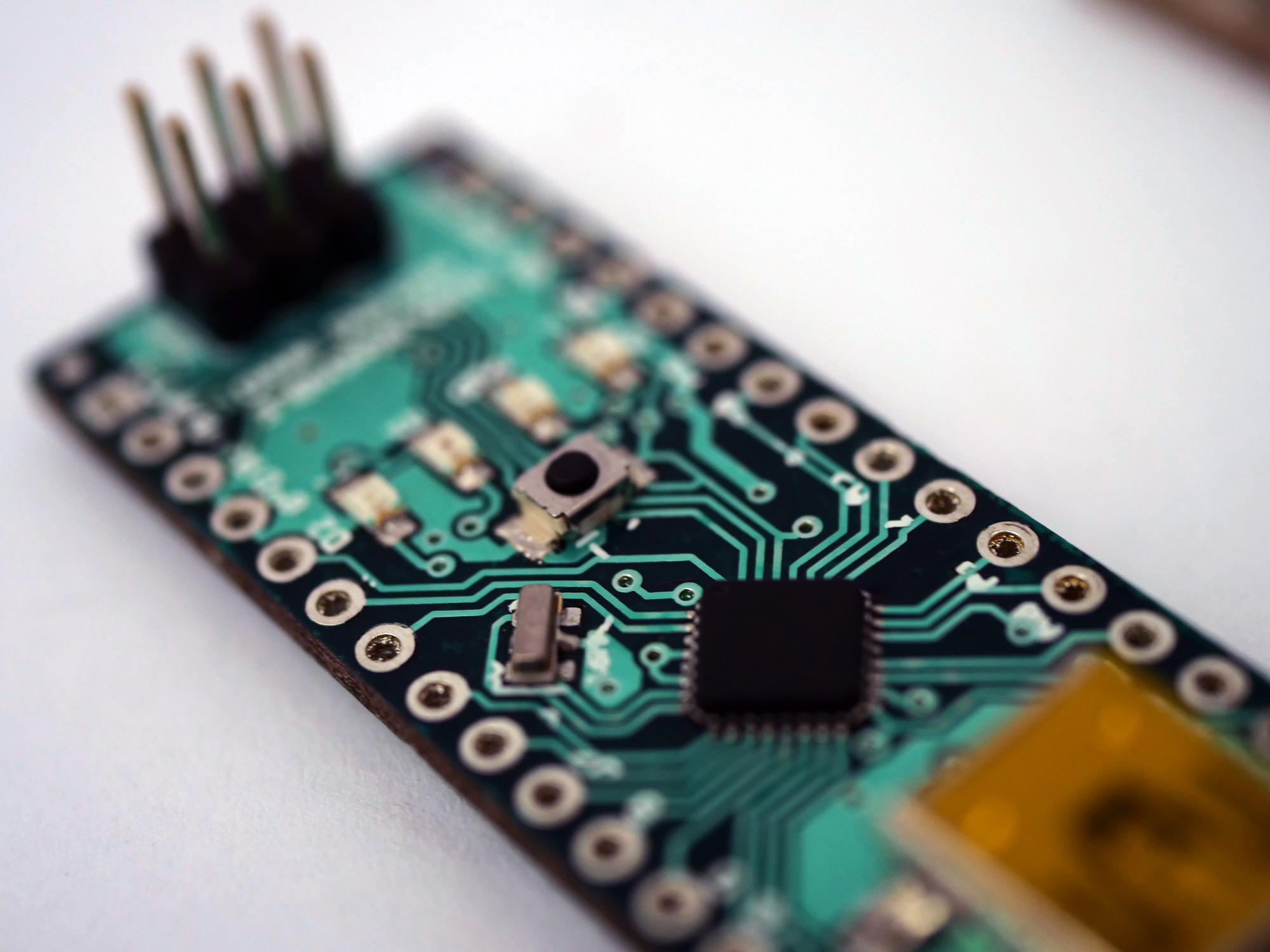

Our Ambition – a world first in PCB innovation

Thanks to a holistic approach, we’ll develop novel and credible solutions for a responsible electronics value chain.

Relying on the interdisciplinary skills of our consortium partners, we aim to develop an alternative, innovative, and low-cost technology of bio-based substrates, increasing CM (Critical Materials) recycling using low-energy and low-pollution innovative bioleaching processes (TRL 1-4).

Our vision is to make the European sustainable electronics goal achievable in everyday life, being able to provide the market by 2030 with environmentally friendly, industrially credible bio-based rigid PCBs with their innovative design and recycling process.

David Cuartielles, ARDUINO

Our Mindset?

Understanding Eco-Design of Electronic Products

This project aims at providing society with a new understanding of circularity in the world of electronics. There are two aspects that control the way we think about this “circular-by-design” eco-design. It looks at the optimization of the process of creating products minimising the environmental impact through the transformation of processes and aspects of the product itself. DESIRE4EU applies principles of eco-design to the manufacturing and recycling process of printed circuit boards (PCBs).

Immediate Effects

Applying this idea to electronics requires analysing the main driver of the field: the production of PCBs. The question we ask ourselves in this project is how to reduce the environmental impact of electronics by the combined effect of repurposing electronic components and later collecting and repurposing the copper on the PCBs. The immediate effect of such an approach will be the reduction of e-waste as a bare minimum, but also the reduction of fresh copper raw material for the production of electronic products.

We need to rethink how we will consider the parts to be included in our electronic designs. The guidelines for the production of electronic products are going to be affected by the limitations of the materials that, such as PLA/Flax, will become part of our bio-degradable electronics. These new materials cannot reach in a few years the levels of integration of contemporary electronics, but that is not a limitation to whatever lays inside the package of chips.

Just Enough

The size limitation in IC-packaging will bring with it yet another interesting consequence: we cannot expose all of the peripherals in ICs. This should bring us to consider which are the most relevant functions we should have available to use whether traditional GPIO pins, communication protocols such as SPI, UART, I2C, native USB and debugging ports, antenna connectors, etc.

But there is yet another limiting factor in the making of more sustainable boards, and that is power consumption.

We can surely pack highly complex computing power into relatively small packages, but do we really need that for the most common applications? DESIRE4EU has set the bare minimum computation level in the possibility of processing some machine learning algorithms. At the time of writing, the TinyML foundation has changed its name to EdgeAI foundation because of the arrival of LLMs to edge computing. There is a tendency always repeated in technological development of trying to place as much computing power as possible at every location. But do we really need such power to run simple edge algorithms looking at trends of a handful one-dimensional sensors?

Therefore we claim that bio-degradable and sustainable computing requires a Just Enough mindset: Just Enough Computing / Consumption / Power and of course, Technology. Following this approach should allow us to transform a majority of the electronics out there, those that are not in mission-critical applications could be bio-degradable or in favour of critical metals recovering following the new design guidelines proposed by DESIRE4EU.

Systemic Change

Reaching this systemic change implies provoking a change in the way we understand electronics. This area of knowledge is in constant evolution, since the arrival of TTL technology, we have witnessed a competition between different entities trying to produce faster components with smaller footprints. The process of producing electronic components is one of the most complex that exists. The production of a microchip requires involving varied sources from collection of raw materials to the final product. It is therefore imperative to figure out anything that will reduce the environmental impact of such a production workflow.

With DESIRE4EU is a unique opportunity to embrace a change that will be of a systemic nature. Bio-degradable electronics will also require optimized manufacturing and recycling processes with less consumption involved. Therefore the systemic change starts at the beginning of the life cycle of the PCB. This is how we embrace circular-by-design departing from a simple change that will have a huge impact on the whole production line of electronics.

Discover more:

EU electronics & sustainability context

Challenging the State of The Art

Transdisciplinarity within DESIRE4EU

DESIRE4EU Impacts