Enhancing Electronics life span and Sustainability with ABChimie in DESIRE4EU

Enhancing Electronics life span and Sustainability with ABChimie in DESIRE4EU

In the transition toward greener electronics, new PCBs must combine reliability with sustainability. In this context, the life span and recyclability of PCBs is a key question that we address within DESIRE4EU. In the consortium, the French company ABChimie provides essential expertise in conformal coatings. These thin polymeric films are designed to protect PCBA from harsh environments in which modern electronics operate.

Conformal Coatings: protecting electronics

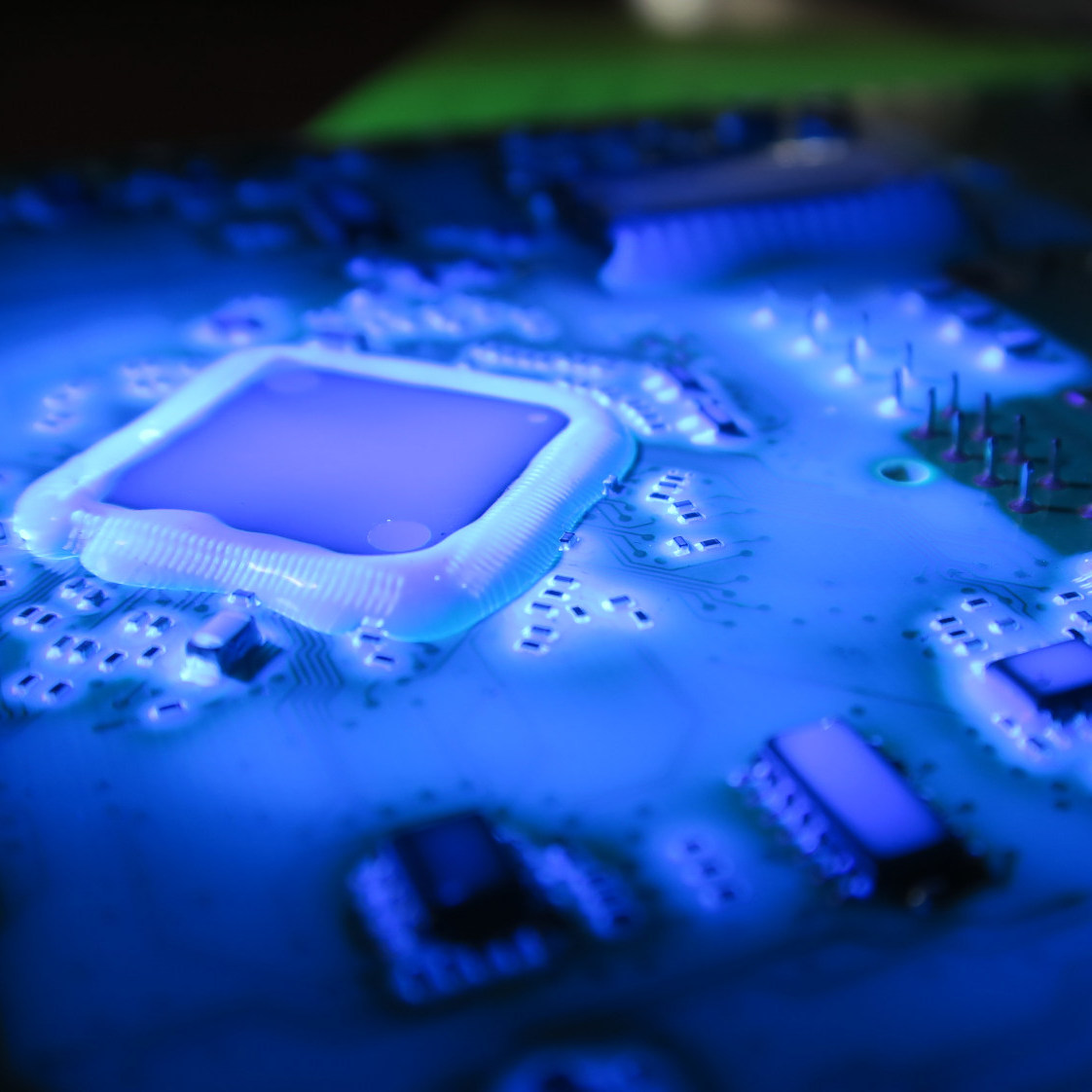

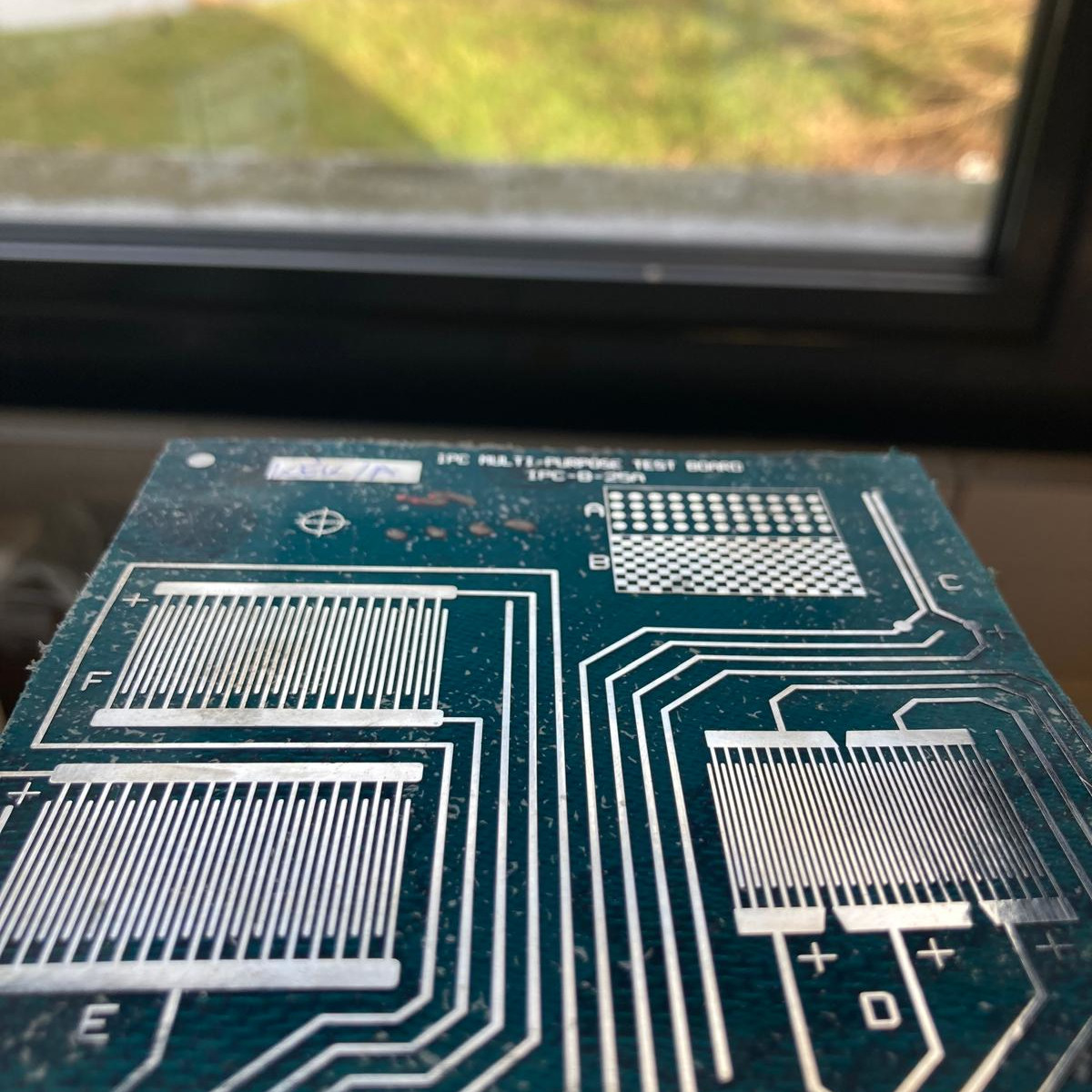

The primary function of a conformal coating is to protect electronic components from possible environmental exposure such as humidity and temperature variations. Moreover, as electronic devices undergo extreme miniaturization, the distance between conductive tracks shrinks, increasing the risk of electrical failure.

By applying a dried thickness between 30 and 130µm (IPC CC 830), conformal coating provides a barrier against all those risks, ensuring the stability of the assembly. Without these coatings, the lifespan of electronics in automotive, aerospace, or outdoor applications would be significantly reduced, leading to premature electronic waste.

The Shift to Bio-sourced and Non-Toxic Formulations

Today, the challenge for this field is to keep those strict performance standards, especially in very harsh environment, while complying with environmental and health considerations.

Within the European Union, chemical development is regulated by the REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) regulation, providing a framework to ensure a high protection of human health and the environment. For ABChimie, the challenge is to identify materials with two goals in mind: being non-toxic, or non-CMR, for human health, and as bio-based as possible to reduce the impact on the environment of the electronics industry.

However, to achieve circularity, the development of such bio-based resins must overcome a number of constraints and challenges. “Standard acrylics are highly reliable because they can withstand significant thermal cycling, while bio-sourced resins do not match this performance”, says Océane Da Silva-Fernandes, chemist at ABChimie. Furthermore, “bio-sourced” does not always means “non-toxic”, add Jean-Pierre Douchy, founder of ABChimie. Careful formulation will then be required to ensure that natural raw materials do not introduce new chemical risks during the process.

“Standard acrylics are highly reliable because they can withstand significant thermal cycling, while bio-sourced resins do not match this performance.”

Fitting conformal coating into the DESIRE4EU Lifecycle

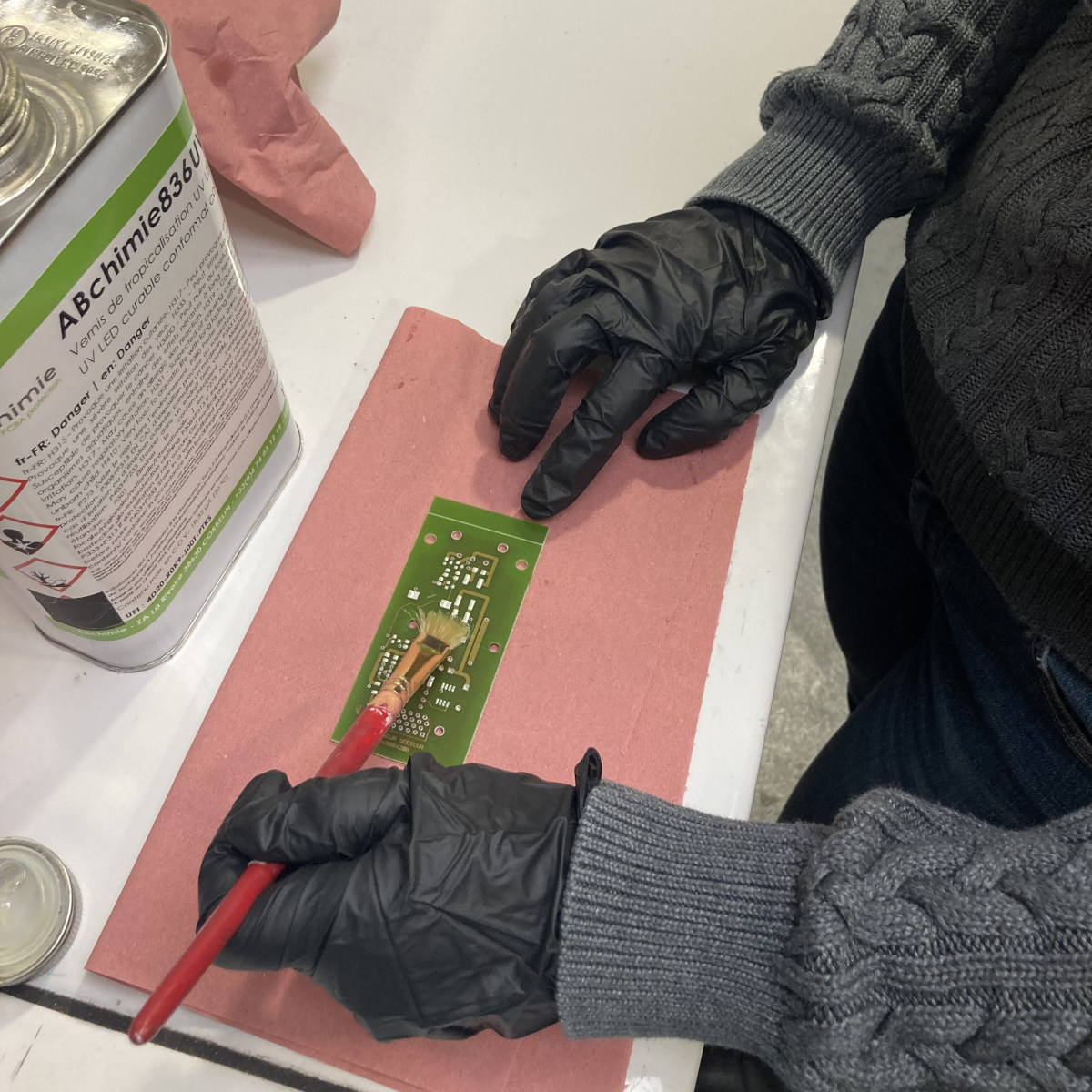

The collaboration within DESIRE4EU will facilitate testing of conformal coatings directly on bio-based materials provided by BME to attest their adhesive performance and compatibility.

Beyond protection, DESIRE4EU addresses the circularity of conformal coating. Currently, two types of coatings are used in the industry. “On one hand, solvent-based coatings, which are easy to remove at the end of the product’s life. But conventional resins must be compatible with the recycling process developed within the project. On the other hand, UV coatings are partly bio-based and solvent-free, which means no VOC emissions into the atmosphere, but they are more difficult to remove”, explains Océane DA SILVA-FERNANDES. Within DESIRE4EU, the challenge will be to study which coatings can be used to be integrated with other processes such as the recycling of critical metals based on bio-inspired process and the use of bacteria.

Balancing high-performance protection with efficient recycling, while going toward fully green PCBs, this is how ABChimie contributes to our project to ensure a sustainable future for electronics.