Challenging the state of the art

to make European sustainable electronics reality

Current limitations and challenges of Pyro- or hydro-metallurgy for CM recycling from WEEE:

- Only Gold and few CM are efficiently recovered

- Polluting chemicals and high energy consumption.

- PCB resins and other non-renewable materials are not recovered and create ultimate waste.

Aim to develop a bioleaching process to:

- recover CM used in the new PCB at a similar scale than previously with a better yeld

- recover bio-polymers by bio-degradation

Added values:

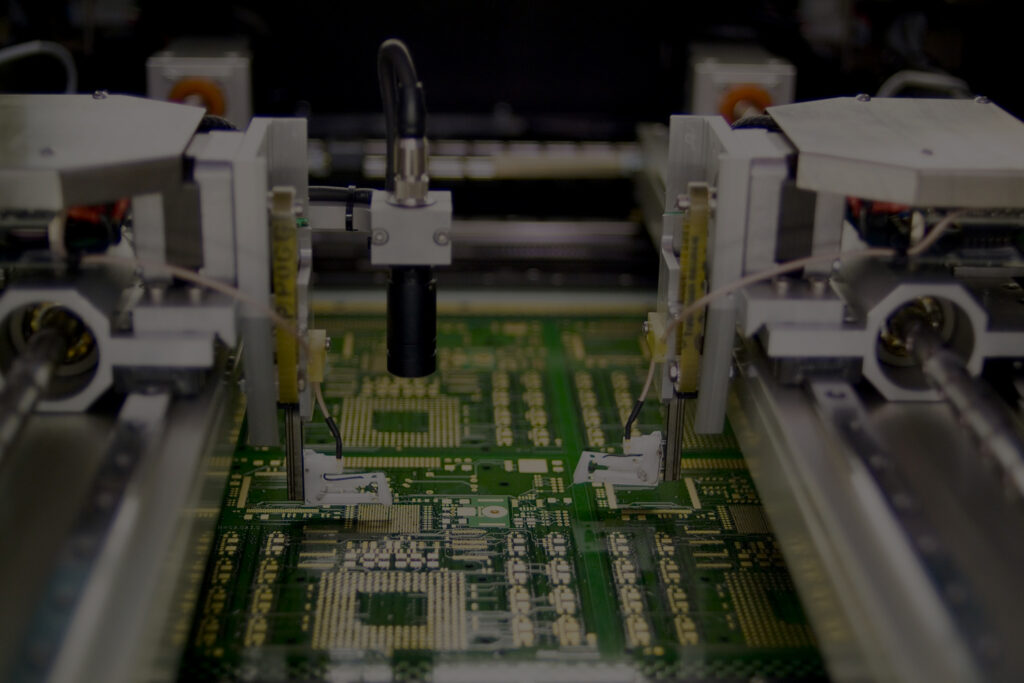

Current limitations and challenges of PCB assembly:

- Photochemical etching of Cu, Pb-free soldering of components with alloys

- High GHG emissions and water eco-toxicity

Aim to develop

- bio-based PCB protection products to slow down its bio-degradation in ambient conditions

- eco-friendly assembly processes.

Added values:

- ability to process bio-based laminates as efficiently as traditional FR4 laminates

- lower environmental impact.

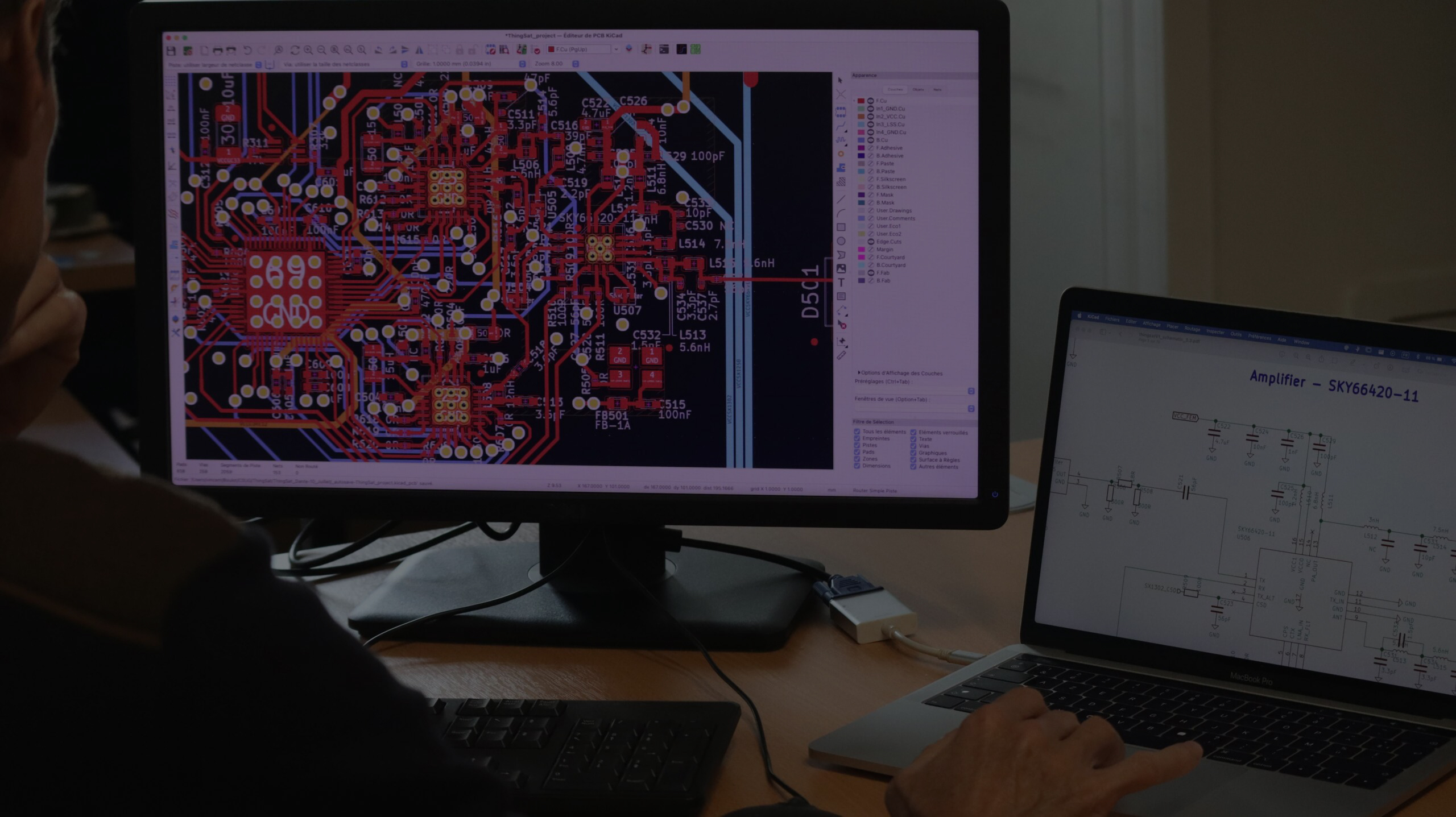

Current limitations and challenges

- Materials of petrochemical origin for the dielectric part of the PCB, such as epoxy resin

- Strong negative environmental impact

- Non-degradability of conventional PCB materials

Aim to develop new dielectric materials compliant with most of the criteria of IPC standards

Added values:

- Reduction of the non-renewable resources consumption and fossil fuels dependency

- Reduction of GHG emissions

- Controlled biodegradability.

Current limitations and challenges of Electronic boards design rules:

- don’t consider the possibility of optimizing the end-of -life of electronic products regarding components reuse and CM recycling.

Aim to develop new eco-design rules able to maintain the overall performance of the electronic circuits while maximizing the circularity of the boards.

Added values:

- New design rules and modular approach will lower boards environmental footprint

- prepare the European PCB Industry for new regulation (FR4 possibly be banned).